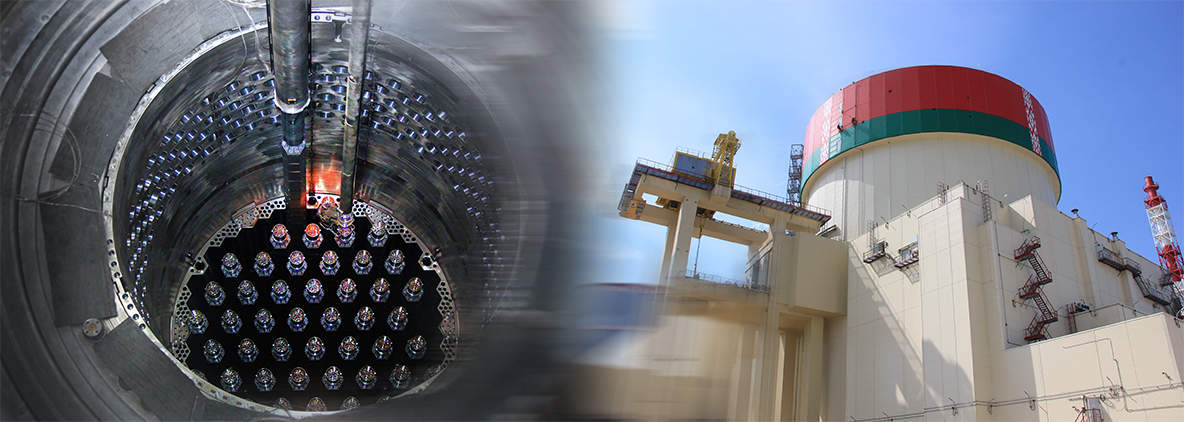

This technological process is included in the set of mandatory control measures at the stage of preparation of power units for commissioning. The purpose of the ECC is to confirm the safety of the technical characteristics of the metal of the main equipment of the reactor compartment after the hot run-in.

According to the head of the representative office of Atomenergoremont JSC in Belarus Andrei Zalozny, eddy-current control of the equipment of Belarusian NPP was carried out according to a unique method using high-precision devices and manipulators manufactured by Atomenergoremont specialists and having no analogues in Russia. The essence of the method is to measure the speed and depth of the passage of currents through the metal. These data draw conclusions about the state of the material, to detect cavities, longitudinal and transverse cracks of even minimal sizes. "Simple and at the same time reliable manipulators make it possible to bring measuring instruments to any point for carrying out measurements, and devices for fixing data can work for many hours at maximum loads. The study is carried out with maximum accuracy, the reliability of detection of metal defects is close to 100%," - representatives of the company said.

Not only the schedule for carrying out related commissioning, but also the timing of the audit of the main equipment of the reactor installation depended on the timeliness of the ECC. “The coordination of actions, efficiency and the highest professionalism shown during the execution of work by all participants in the process from the Russian and Belarusian sides completed this production phase on time without loss of quality,” said Oleg Shperle, ASE IC Vice President.

Belarusian NPP with two VVER-1200 reactors with a total capacity of 2,400 MW is being built under the Russian project near Ostrovets (Grodno Oblast). The general contractor is the engineering division of Rosatom State Corporation. The commissioning of the first power unit is scheduled for 2020, the second - in 2021.