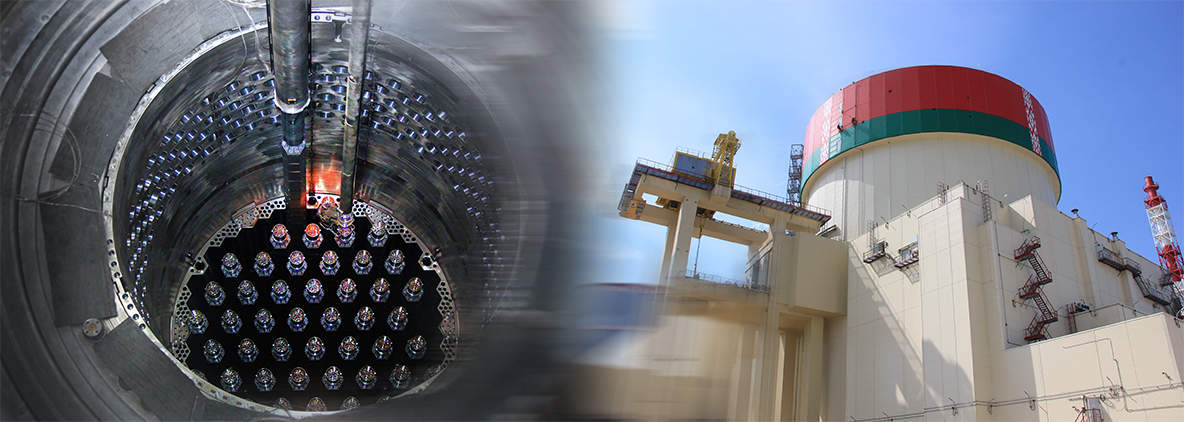

Prior to this, a "melt trap" was mounted at the first power unit, concreting of the support and thrust trusses was carried out, and dry protection and thermal insulation of the cylindrical part of the reactor vessel were installed. Immediately before the installation of the reactor vessel, a support ring was mounted, which carries the main weight load of the vessel.

"I would like to note the impeccable work of the assembly team and the operators of the lifting equipment. Installation of the vessel requires jewelry precision: the maximum permissible horizontal deviation does not exceed a tenth of a millimeter. Completion of the vessel installation will continue work on the construction of the reactor shaft," said the first deputy general director of JSC “Akkuyu Nuclear ", director of Akkuyu NPP under construction Sergey Butskikh.

The progress of the installation operation was monitored by representatives of the Nuclear Regulatory Agency (NDK), an independent organization for construction control - French engineering group Assystem, the experimental design bureau Gidropress (designer of the Akkuyu NPP reactor plant) and AEM-Technologies - the manufacturer of the reactor vessel.

The installation of the reactor vessel was carried out using the Open Top technology - through the open top of the cylindrical part of the reactor building. It optimally combines construction and installation operations, begins installation of equipment and pipelines before the completion of concreting floors. The technology has successfully proven itself in many projects for the construction of nuclear power plants in China, Japan, Bulgaria and Russia, including the construction of power units of Leningradskaya NPP-2 with VVER-1200 reactors. With the use of Open Top, it is planned to install steam generators, pressure compensators, main circulation pumps and other main technological equipment of reactor buildings at Akkuyu NPP units.

After the installation of the reactor vessel, the builders will continue concreting the reactor shaft, set supports for the components of the main circulation pipeline (MCP) and steam generators. After the installation of steam generators and casings of the main circulation pumping unit, it will be possible to start welding the MCP connecting the main equipment of the primary circuit of the NPP.

The reactor vessel of power unit No. 1 was delivered to Akkuyu NPP construction site by sea in November 2020. After the vessel was unloaded at the Vostochny sea cargo terminal, the hull was transported to the storage site, where it underwent an incoming control procedure, which confirmed the integrity and high quality of workmanship.